In today’s market ,the Marketing value of any product is determined not only by its quality but also by its packaging . Blister packaging in particular , is considered the safest most attractive , and cost –Effective solution for products of all sizes. If you wants customized blister packs for you product , we offer all these service in one place .

What is a blister ?

The blister pattern is the design / shape on which the blister is made .

It determines that:

- What will be the shape of the cavity .

- How many cavities will there be ( 2s , 4s, 6s, 10s).

- What will be the depth of the cavity round or oval tablet shape .

- Product be sold and how should it be kept.

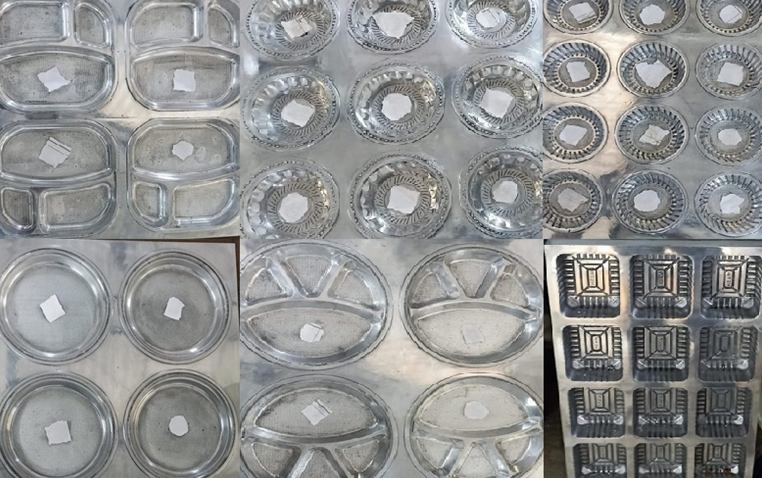

Types of blister pattern

- Standard tablet pattern

Round tablet

Oval tablet

Capsule tablet

- Single cavity blister

Single cavity for a single product

Uses – USB , SMALL TOOL ,COSMETIC Item.

- Multi cavity uniform blister.

All cavities are the same ( pharma tablets / capsules).

- Multi cavity non – uniform blister

Cavities of different sizes .

Like – hardware kit ,toys accessories .

- Carded blister pattern

Blister + card packaging.

Common in FMCG.

- Slide blister pattern

The card is slide inside the cavity.

High security packaging .

- Full face blister pattern

The entire card is covered with a blister pack.

Cosmetic and retail .

- Trapped blister pattern

Blaster are trapped between two cards .

Tamper proof premium packaging .

Types of blister packaging

1.Thermoformed blister

The material are heated and then formed .

Material : Pvc , PET , PETG , HIPS

Most common & economical .

2. Cold formed blister ( CFF)

Aluminum –based laminate

The pharma is product for moisture barrier.

100% light & moisture barrier .

3.Face seal blister

Heat sealed by Blister card .

Most common in retail.

4.Full card blister

Complete card in blister cover.

5. Clamshall blister

Hinged two slit halves

Reusable +blister

Popular in electronics and tools

6.Trapped / Hybrid blister

Eco friendly

Cardboard + blister

What is blister Dye

Blister Dye is a metal mold or shipping tool used to create a blister cavity .

Types of blister Dye

Thermoforming pie :The cavity is created using vacuum / pressure.

Cold forming : The aluminum laminate is shaped under pressure .

Punchs Dye set : For all cutting

Sealing pie:

- The blister pack is sealed with a card / foil.

- Useful for blister sealing .

The main material in blister packaging

Film / cavity material

- Pvc

- PVDC coated PVC

- PET / PETG

- HIPS

- Polypropylene

- Cold form aluminum

Backing / lidding material

- Paperboard

- Aluminum foil

- PET – coated foil

- TYVEK ( medical)

Types of blister packaging machines

- Rotary thermoforming blister machine .

- Flat forming blister machine .

- Pharma blister packing machine .

- Manual / semi-automatic blister machine.

- Clamshell blister sealing machine .

Benefits of blister packing

Product visibility

Tamper resistance

Cost-effective

Branding & graphics possible

Moisture/ light protective ( CFF)

Lightweight & easy to hang / display

Where is blister packaging used?

- Pharmacceuticals ( tablets / capsules / syringes)

- FMCG products

- Toys

- Electronic

- Hardware tools

- Cosmetics

- Retail display items

Blister packaging has become a reliable , secure and attractive solution for every industry . The right design and strong blister pack significantly enhance both the quality and appeal of your product . our team provides you with a complete solution in one place , creating custom patterns , packaging ,and blister dye tailored to your needs . whether your production is small or large , we guarantee high quality and timely delivery at every stage . If you want your product to stands out in the market , packaging and custom blister Dye from our company are the right choice , and we make it easy for you .